Hydroforming production

We offer in-house production for Tiers 1-3. Our capabilities range from small to large volume series production to production support for other hydroformers who have run out of available capacity.

We offer in-house production for Tiers 1-3. Our capabilities range from small to large volume series production to production support for other hydroformers who have run out of available capacity.

Schuler’s production site can support all bottlenecks common to hydroforming production—this includes producing small batches and prototypes.

At Schuler North America, our plant utilizes two large presses to produce hydroforming tubes specific to the automotive, agriculture, construction, and recreational markets. As a full-service provider, we can assist in the development of hydroformed tubes or manufacture an already developed product. Schuler’s in-house processes include bending, preforming, hydroforming, laser cutting, and minor assembling as needed.

We are happy to help with:

Engineering and development

Hydroforming production

Minor assembly

Validation

Advanced development

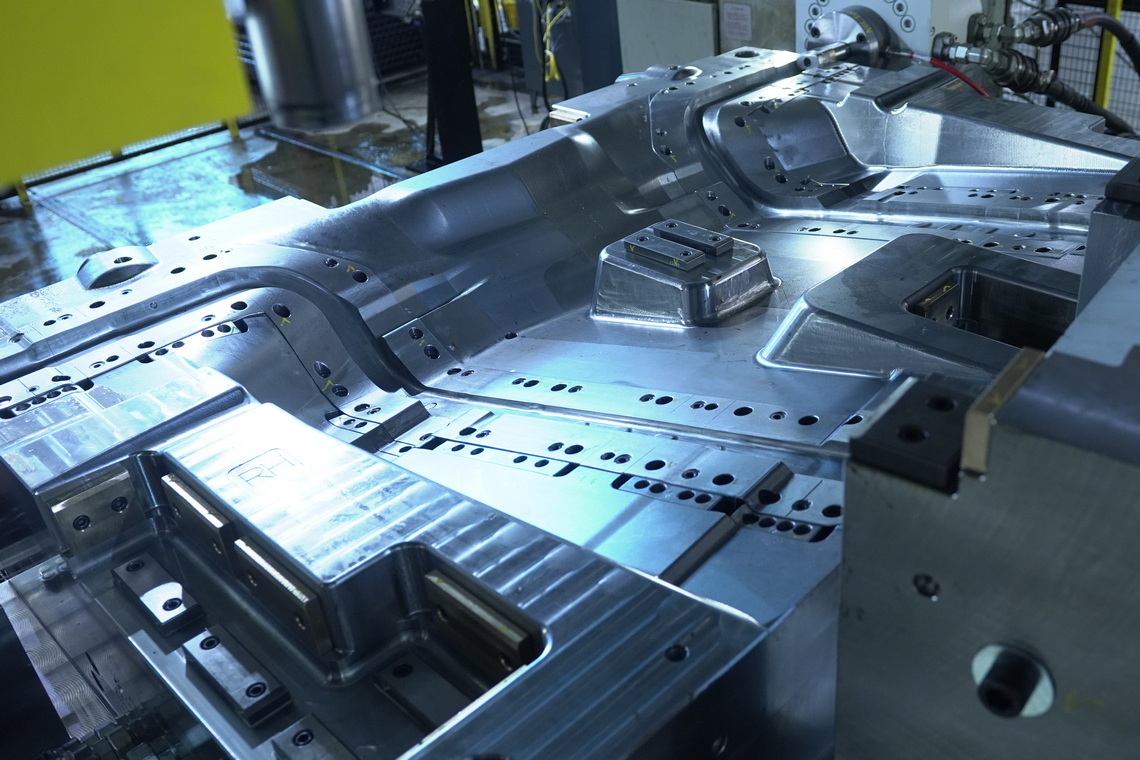

Schuler develops and produces hydroforming tooling, from prototype testing to full production dies. Dies can be run in-house or at customer facilities with worldwide start-up support.

Learn more

Schuler provides full turnkey hydroforming solutions—including design, feasibility and tryout support.

Learn more

Chris McMahon

Sales Manager, Hydroforming

location_on Schuler Incorporated Canton

Klaus Hertell

Vice President, Hydroforming

location_on Schuler Incorporated Canton